Innovating Techniques

The Fastwall

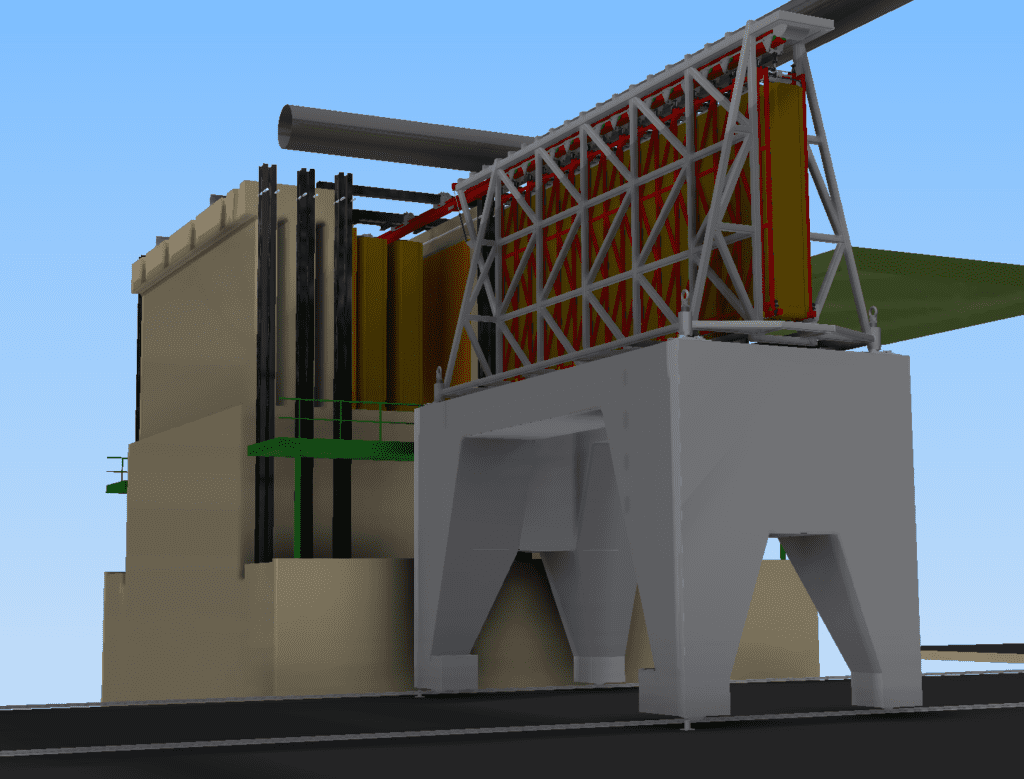

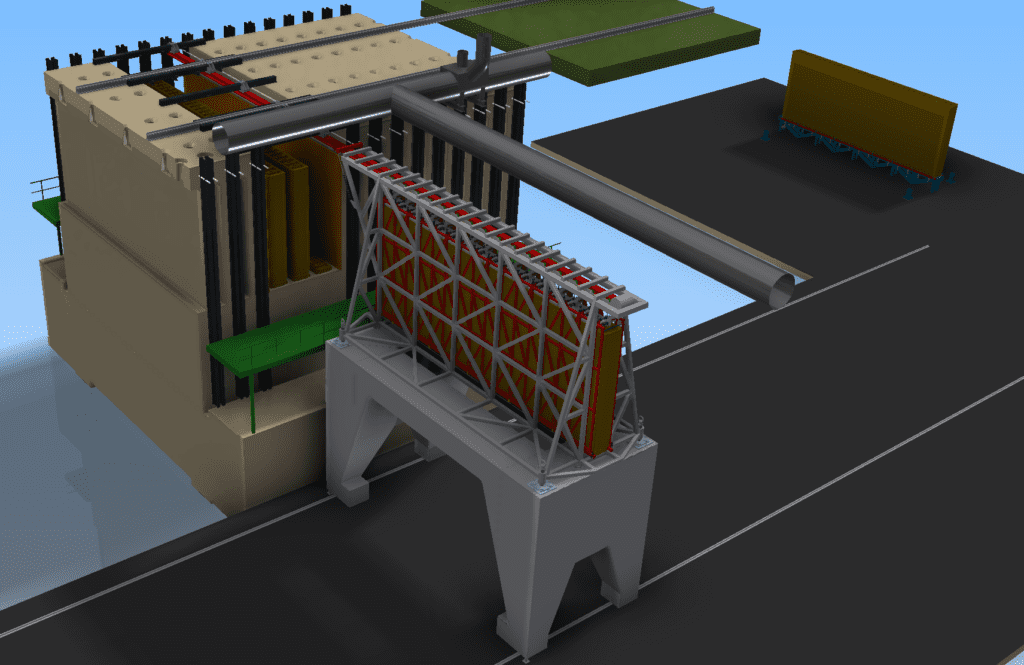

HeatTeQ has developed a new patented concept to replace a coke ovenwall, called The Fastwall Concept. Unique to this concept is that the coke ovenwall is built at an external location, instead of in the battery itself. In short, the wall is lifted while being supported by a truss structure and placed on a transport. During the lifting and transportation, hydraulic cylinders will keep the wall levelled.

The levelling cylinders ensure the stress in the bricks of the wall is equally divided. Due the equally divided stress and the way of lifting, the bending stress and tensile stress are significantly reduced to almost 0 MPa.

When arriving at the battery, the wall is lifted on a construction positioned in front of the oven. The oven is entered by riding the wall, together with the truss structure, over a rail. Then the wall is placed on the first layer of fused silica bricks. Finally, the truss structure is released from the wall and removed from the oven, allowing the process to repeat itself in order to place the next wall.

Benefits:

Significant increase in labour safety

Since the building of the wall is done at an external location, the number of man-hours spent in the inhumane working environment of the repair areas are substantially reduced. Moreover, using task risk analysis, we have theoretically proven that the risk of an accident will decrease by more than half.

Increased process efficiency reduces labour costs

While it normally takes ±90 days to demolish and repair three walls, it will only take 35 days when using The Fastwall Concept. Thus, labour costs and coke loss will significantly decrease. Which leads to lower cost for the customer.

Cobra Grinder

A new innovative system for grinding of blast furnace carbon

- Time saving

- Cost saving

- Furnace downtime saving

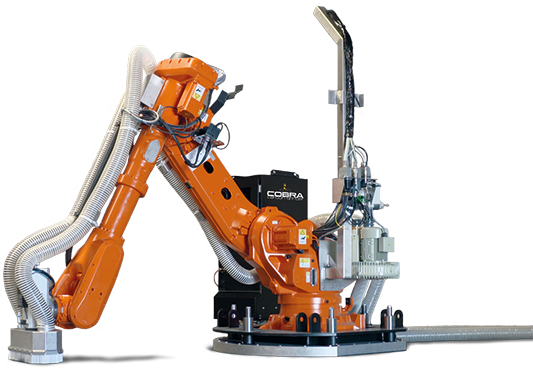

The demand for quick and safe maintenance solutions becomes more and more important for blast furnace operators. Downtime (loss of production) thus total repair costs are to be kept to the bare minimum. The solution? Cobra Carbon Grinder.

What it can do for you…

With lining replacement in furnaces, it is often required to adjust the top elevation of the floor in order to meet the new wall design. The Cobra Carbon Grinder is a robotic grinding machine able to reach the required floor elevation over the entire floor surface, independent of furnace diameter with an accuracy of less than the 0.5 mm acquired.

Time saving…

Instead of the normal 5-8 days, the Cobra Carbon Grinder completes the work in 2-3 days, saving time and money.

How it works

The robot receives its coordinates from a laser scanning survey instrument by means of a wireless communication system. This assures the exact same elevations throughout the furnace, irrespective of the diameter. A specially designed hood extracts all fines and dust, optimizing work conditions in and around the furnace.

MySEPP

The best platform to eliminate risks on the workplace! MySEPP is an online software platform that lets you manage the day-to-day HSE activities on a real-time basis. By combining contemporary possibilities, MySEPP automizes and simplifies standard HSE management procedures; diminishing paperwork, controlling and clarifying actual costs made on HSE. MySEPP offers the following features:

- Last Minute Risk Analyses

- Safety Report

- Work Place Inspection

- Automated Report management

- Real-time risk management

- Risk visualisation

- HSE performance analysis