QUALITY

Trust is a good thing, but control is better. Choosing the right material and installation in accordance with the necessary tolerances can make a major difference to your operation. Get the facts.

SAFETY

We work closely with our customers to build a strong safety culture for working in the field leading to improved safety performance. We make sure our repair systems are well designed, safe to operate and easy to maintain.

EFFICIENCY

Making it possible by offering extended services, improved plant productivity and a focus on reducing asset owner’s energy and operating costs. We are committed to taking every step required to lower our customers carbon footprint.

QUALITY

Trust is a good thing, but control is better. Choosing the right material and installation in accordance with the necessary tolerances can make a major difference to your operation. Get the facts.

SAFETY

We work closely with our customers to build a strong safety culture for working in the field leading to improved safety performance. We make sure our repair systems are well designed, safe to operate and easy to maintain.

EFFICIENCY

Making it possible by offering extended services, improved plant productivity and a focus on reducing asset owner’s energy and operating costs. We are committed to taking every step required to lower our customers carbon footprint.

WHAT WE DO

We provide the industry with the full range of services for furnace repairs with a constant aim for quality. Our management is continuously and fully engaged in customer activities. We offer custom services and can respond quickly to changes and unforeseen circumstances. Our customers describe working with us as easy, due to the quality of feedback and transparency, and pleasurable, because of our personal approach and involvement. We offer a durable, high quality final product for the best price.

We spend time on the wellbeing of our employees and respond to demands to make it even better. A healthy company can bring the highest quality.

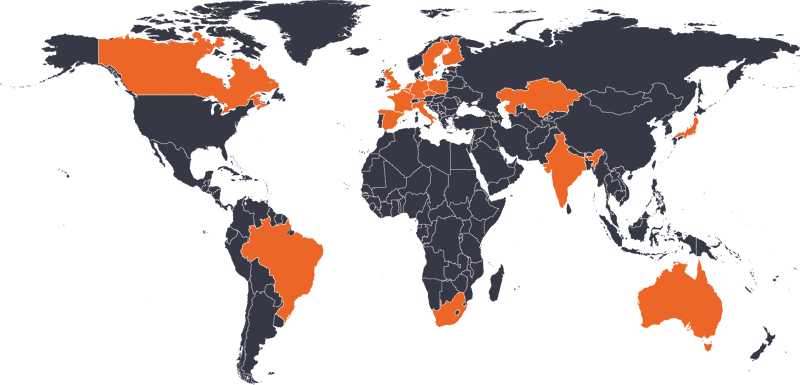

WORLDWIDE SERVICES

Check out our current project locations around the world:

Australia, Austria, Belgium, Brazil, Canada, Czech Republic, England, Finland, France, Germany, India, Italy, Japan, Kazakhstan, Netherlands, Poland, South Africa, Spain, Sweden.